What is a liquid flexible pouch?

For many years, flexible pouches have been associated with dry products mainly used for foods such as coffee, cereal, and dog treats. However, in recent years, liquid pouches are being adopted in various applications, from personal care to automobile products, because of their sustainability benefits. Even though dry and liquid pouches share similar styles, liquid pouches require more technical testing and performance review to hold products safe and secure. You may think, “why cannot I just add a spout to a dry pouch?” but that is not the best practice for many non-food liquid products for many reasons. Let’s find out why.

Feature Resource

- What is a refill pouch? Everything you need to know, from the materials to the benefits of refill pouches.

- 4 Reasons to Choose Flexible Refill Package

Benefits of liquid pouches

First, let’s go over some benefits of liquid pouches. A liquid pouch offers both sustainability and usability benefits.

Compared to a rigid bottle, a spouted pouch uses significantly less plastic. The rigid bottle of 4 fl. oz (118ml) weighs 17.4g; on the other hand, the spout pouch weighs only 5.9g.1 That is over 65% less plastic used in the packaging. Besides, a liquid pouch reduces the overall carbon footprint in the whole packaging lifecycle stage from manufacturing and transportation to disposal.

In addition to sustainability benefits, liquid pouches are incredibly versatile and easy to use. Some of you may have tried refilling a bottle with a soap or shampoo refill pouch. It is super easy to refill and empty. Especially if you are refilling high-end personal care products, you want to empty them as much as possible. Liquid pouches can make that happen. So now that you know about some of the liquid pouch benefits let’s jump into the differences between liquid and dry pouches.

Why do liquid pouches need to be different from dry pouches?

There are commonalities between dry and liquid pouches. First, both pouches look alike. Some pouches are stand-up pouches with a bottom gusset. Some are pillow-style pouches to lay them flat. Second, standard dry and liquid pouches both laminate various films using similar equipment. So, what are the differences? There are three main reasons why typically, it is not a good idea to put a spout to a dry pouch for liquid products.

Reason 1: Liquid products are heavier than dry products

Shampoo is much heavier than chips in the same size packaging. As you learned in the physics class, the energy at the impact point can be calculated as E=mgh (E: energy, m: mass, g: gravity, h: height). The heavier the contents, the higher the impact. Hence, liquid pouches require greater durability.

Reason 2: States of substances are different

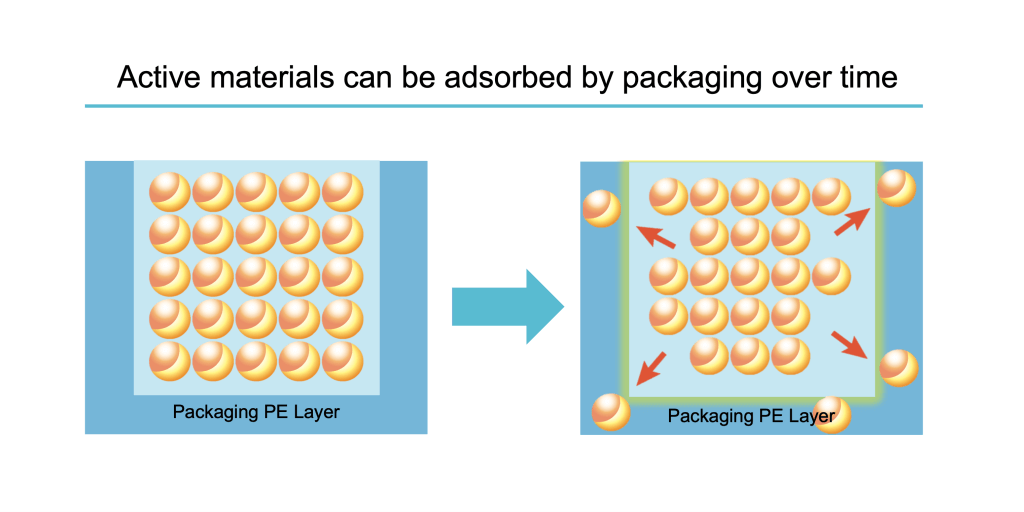

In addition to the weight, states of substances matter for packaging. Both liquid and solid are made up of particles. The difference between liquid and solid is that the particles in a liquid are free to flow, and particles in a solid are not. That means particles in the liquid can move to interact with packaging easily. And typically, personal and home care liquids have more “aggressive” chemicals that can interact with materials causing delamination (delamination = separate films layers apart). Or some chemicals of liquids may be absorbed by packaging materials resulting in less effects of the products. For example, Vitamin E, typically found in cosmetics, tend to leach into the PE layer over time. Thus, selecting a proper combination of films and materials depending on the types of chemicals becomes an essential element for a liquid pouch.

Reason 3: Leakage is a big disaster for liquid products

Quality is critical, especially with a liquid pouch. A Liquid pouch needs more testing to ensure the quality because liquid leaks from a tiny little hole. On the other hand, dry products such as cereal will likely stay in the packaging; even if the pouch has a hole or cut. Therefore, pouch suppliers need to be aware of all the testing necessary to verify the quality.

These are the three main reasons why you cannot just add a spout to a dry pouch for liquid products. Liquid pouches require higher performance. And chemical compatibility with the product becomes a key component. Partnering with knowledgeable pouch suppliers becomes critical for the success of your liquid pouch.

How ZACROS can help

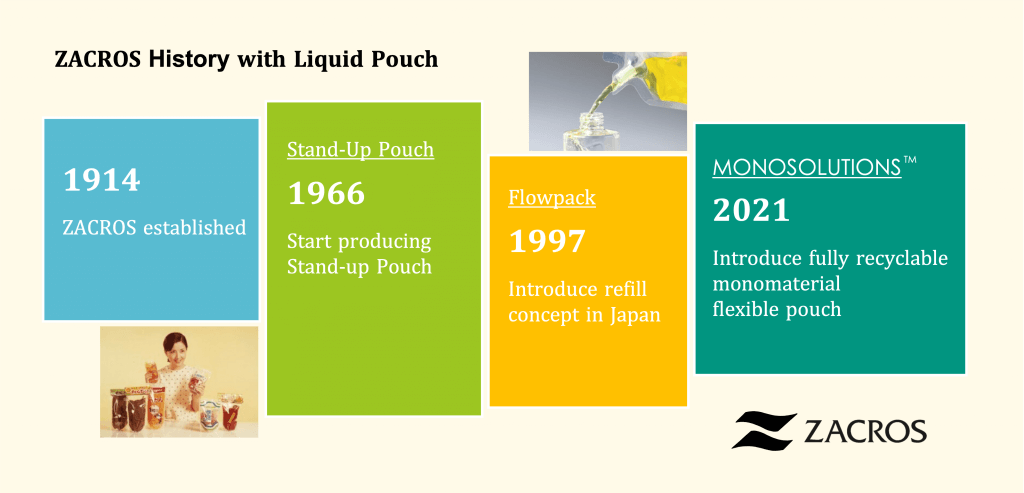

ZACROS has manufactured over 8 billion liquid pouches for personal and home care products in the last 25 years. We know all types of materials that work in this market. ZACROS offers a wide variety of liquid pouch options for any sustainability requirements. Contact us to learn more.

- According to ZACROS internal measurement.